Automation Platform

END OF LINE BUFFER AND REWORK STATION

TECHNICAL HIGHLIGHTS:

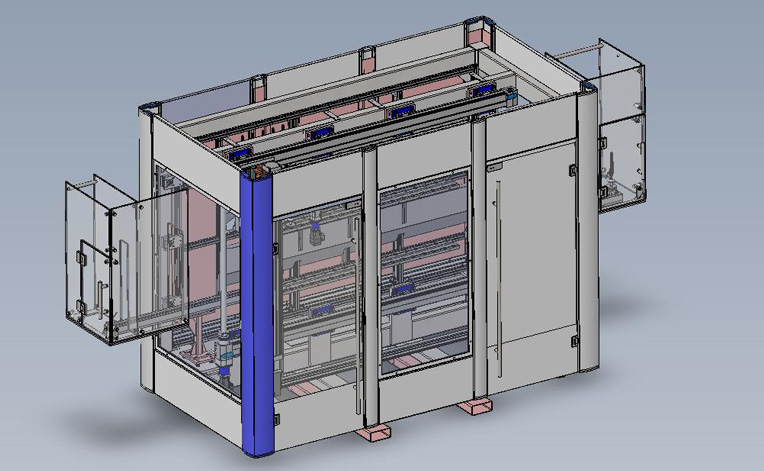

- Footprint w/o conveyor [mm]: L:2.960 x H: 2.380 x D:1.500

- Storage capacity: 200 packages (into 50 buffer slots)

- 4 packages/buffer slot

- Automated servo motor driven 3- axes rack handling system with two-part gripper for flexible blister pack transfer and buffer rack load-/unload.

- MES maintains 100% part traceability and buffer inventory

- Suitable for medical products

- Capable of being integrated into automated system (i.e. labelling system)

- High reliability, minimum maintenance required

- Cleanroom class ISO 8 or higher

- Intuitive HMI design

The IMSTec End of Line Buffer (ELB) and Rework Station is a subset of a fully automated production line for packaging orthopaedic parts. The End of Line Buffer and Rework Station provide a controlled waiting area for finished products that could form part of an incomplete batch awaiting reunification of re-worked packaged parts. The End of Line Buffer loads and unloads packages via a 3-axis servo motor driven rack handling system. The buffer rack can store up to 200 parts. A conveyor moves the parts onto carrier from the load position through the ELB and to the unload position.

Technical data summary

|

|

|

|

|

|

|

|

|

|