Process Solution

Stent Inspection and Measurement System

TECHNICAL HIGHLIGHTS:

- Modular design – can be attached to a cluster system or work as stand-alone

- Semi- or fully automated solution

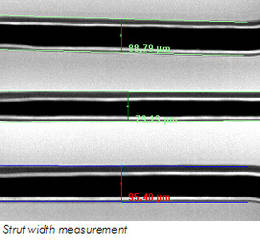

- Measurement resolution approx. 1.5µm/pixel

- Inspection of outer and inner stent surface

- Wall thickness measurement

- Modular recipe design

- Cleanroom class ISO 8 or higher (fully automated version)

- Up to 3 inspection stations per automated module

- Intuitive HMI design

- Automatic handling system (automated module)

The IMSTec Stent Inspection System represents a high end solution for stent inspection and geometry measurement. The system is available as semi- and fully automated version. Stent geometries are measured very accurate and defects on the outer and inner surface are detected. The fully automated version comprises an automated handling system in order to minimize operator interaction.

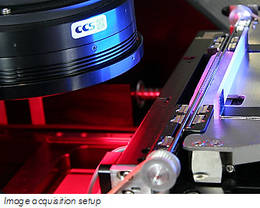

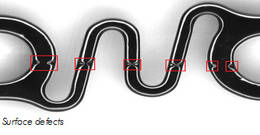

IMSTec’s stent measurement and inspection system detects defects on stent geometries. Strut widths of the stents are measured before and after polishing process. A line scan camera creates high-resolution images of the rotating stent. The analysis algorithm runs on several client computers in order to optimize process time. Modular inspection modules allow a product and process step specific recipe management. New products can be taught easily.

Depending on user requirements a fully or semi-automated system can be provided. The fully automated version can be attached to a cluster system or work as stand-alone as the semi-automated system. For ease of use, with minimal user interaction, the fully automated stent inspection system is embedded into an automatic handling system: Stents are sorted on logistical trays that are loaded into the machine. Up to four trays can be loaded so that the machine can run autonomically for some hours. The semi-automated system requires single part input by the operator. The usage of mandrels can be provided if required.

Once a stent is loaded, the process is the same for both machine versions: The stent is rotated on the spindles and the line scan camera created a high-resolution image of the stent. The taken images are cut into segments and send to several client computers for analysis. Depending on the recipe settings the strut widths are measured and several kinds of defects are detected on the outer and inner stent surface. An autofocus and a wall thickness measurement can be included if required.

Inspection recipes consist of so-called “inspection modules” that can be combined individually for every product. The dxf data are used to create a distinct recipe for every product type. Inspection parameters (such as blob size, width tolerances…) can be adjusted as required.

The semi-automated system contains a housing that separates the inspection area from the operator. Only the loading area is accessible. The fully automated system is completely enclosed so the operator has only access to the tray load port. Transparent windows around the module allow a permanent observation of the process.