Process Solution

BLISTER PACKAGING STATION

TECHNICAL HIGHLIGHTS:

- Fully automated integration

- Fast and precise robot handling

- Short cycle time (8 parts /min)

- Feasible for medical products and cleanroom

- Adaptable for a wide product range

- Automated loading and unloading

- Minimal user interaction

- Intuitive HMI design

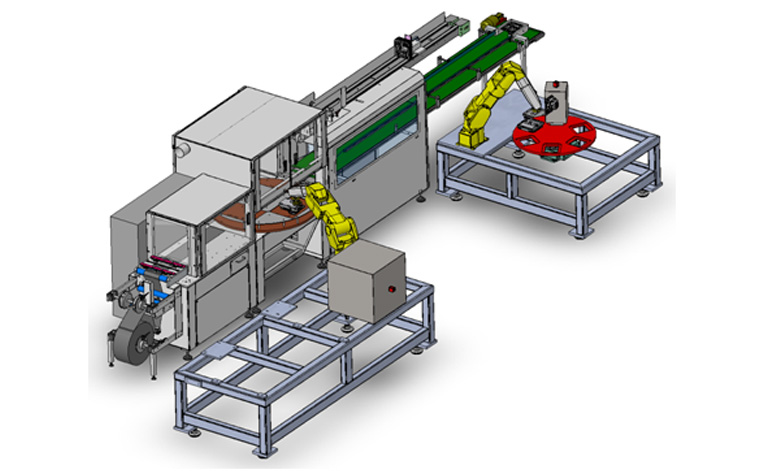

The IMSTec Blister Packaging Station is a fully automatable station for packaging of skin packed medical implants into blister. Several robot systems ensure a fast and precise loading and unloading of the parts. The whole process is triggered and controlled by a PLC. The highly flexible packaging method allows packaging of several different parts.

DESCRIPTION:

One main component of IMSTec’s fully automated packaging system is the blister packaging station. Previously skin packed implants are packed into blisters. Two robot systems ensure fast and precise loading and unloading. An inspection station connected to the system verifies the integrity of each sample. Due to the integrated output buffer the process can be continued during refill of consumables. Except refill of packaging materials no operator interaction is required during the automated process.

Samples packed into blisters are already packed in skin foil on a Tyvek sheet. The load robot grips the part from the skin inspection station and places it on the rotary plate of the blister packer into a blister shell. In the next step a Tyvek sheet is punched and stuck on the blister. Packed parts are delivered to the end of the output conveyor where the unload robot transfers them to the blister inspection station.

The system works fully automated; only refill of the Tyvek roll and the blisters needs to be done by the operator. The whole Automated Packaging Line is surrounded by a housing in order to protect operators from robots and other moving parts. Additionally the moving parts of the blister packer are enclosed.