Process Solution

AUTOMATED SKIN PACKACKING STATION

TECHNICAL HIGHLIGHTS:

- Fully automated integration

- Fast and precise robot handling

- Flexible gripping position adaption

- Short cycle time (less than 1min for 12 parts)

- Feasible for medical products and cleanroom

- Adaptable for a wide product range; different products can be packed together

- Automated loading and unloading

- Minimal user interaction

- Manual mode possible

- Intuitive HMI design

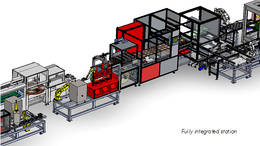

The IMSTec Skin Packaging Station is a fully automated station for packaging of medical implants. Several robot systems ensure a fast and precise loading and unloading of the parts. The whole process is triggered and controlled by a PLC. The highly flexible packaging method allows the combination of several different products on one sheet.

DESCRIPTION:

One main component of IMSTec’s fully automated packaging system is the skin packaging station. Samples are placed on Tyvek sheets and sealed by hot skin foil. The foil adjusts its shape to the sample’s geometry so the packaging method can be used for almost every sample up to a certain size. Robot systems with built-in camera systems provide accurate part handling of the cut samples. No operator interaction is required during the automated process.

Samples to be packed on the skin packaging station are prepared by robots within the load station. Twelve parts are placed on a Tyvek sheet in plastic shells and then transferred into the skin packer. A foil is heated above the samples and then moved down. The hot foil adjusts its shape exactly to the parts and sticks tightly on the Tyvek surface. Thus the parts are packed hermetically. A die cutter cuts handy pieces that are transferred to the output station where a robot takes the packed parts from the conveyor. A camera system on the robot’s head identifies the exact position of the package and allows a precise position adaption.

The highly flexible packaging and handling methods allow processing of a wide range of different products. It is even possible to pack different sample types on one Tyvek sheet.

A mostly transparent housing around the skin packer provides operator safety with the chance to observe the process.