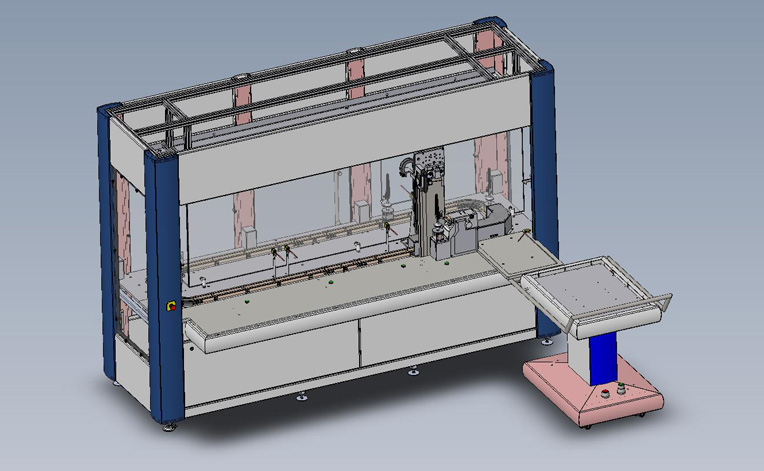

Automation Platform

AUTOMATED INCLAIM BUFFER STATION

TECHNICAL HIGHLIGHTS:

- Footprint [mm]: L:4100 x H: 2.460 x D:3.200

- Storage capacity: 440 parts

- Supports 30 min. uninterrupted line run time without the need for operator interaction

- Automated servo motor driven 3 axes rack handling system for flexible tray load / unload and positioning.

- 100% part traceability and inventory

- Full unload flexibility (FiFo, freely configurable)

- Batch or single part processing

- Logistic tray capacity: 20 parts/tray

- Wide product range, usage for different products in parallel possible

- Suitable for medical products

- Capable of being integrated into an automated system (i.e. part verification)

- High reliability, minimum maintenance required

- Cleanroom class ISO 8 or higher

- Intuitive HMI design

The IMSTec Inclaim Buffer Station (AIS) is an automated system for storing incoming orthopaedic parts located on logistic trays at the introduction of part(s) to the Production Line. As part of a fully automated process its main purpose is to maximize productivity by decoupling the automated process from operator driven processes. The buffer station comprises a load and unload port, a buffer rack with 22 slots for filled logistic trays, this design can also be used as an output buffer. Inventory control with full traceability is also offered and is achieved through an integrated RFID reader in the Logistic trays.

DESCRIPTION:

IMSTec’s fully automated inclaim buffer station targets fast, safe and reliable load/unload and storing of medical products within a fully automated production line. The parts are located on a logistic tray with a capacity of 20 parts/tray fed via the load port. The rack handling system transports the logistic tray from the load port into a free rack position and then transports from the rack position to the rack unload position. The buffer rack has a capacity of 22 slots for filled logistic trays. This enables an automated operation for at least 30 minutes without need for operator interaction. The output buffer has a capacity of 24 empty logistic trays.

After the logistical trays are loaded, RFID information (batch data, number of parts) is read and sent to the LAS by the HMI. As a result the LAS will return the appropriate recipe to the HMI.

The buffer station is part of a fully automated production line whereby a robot successively picks all parts from the logistic tray and moves them through a PVS (Part Verification System) process. To unload empty logistic trays a corresponding request has to be sent via the HMI. The requested tray is transferred from the output buffer to the unload conveyor where they can then be manually processed.