Process Solution

SKIN PACK INSPECTION STATION

TECHNICAL HIGHLIGHTS:

- Fully automated integration

- Fast and precise robot handling

- Rotating index table

- Compact footprint [mm]: L:1400 x W:1100 x H:1.800 (depends on product size)

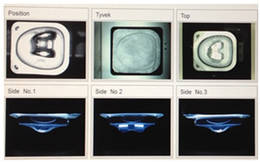

- All-side inspection with three camera systems incl. LED illumination

- Feasible for medical products and cleanroom

- Modular design – number of stations adapted according user requirements

- 100% non-destructive inline inspection of packaged parts

- Adaptable for a wide product range

- No user interaction necessary

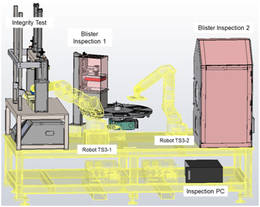

The IMSTec Skin & Blister Pack Inspection Station is an automated operating station which controls the packaging quality of skin- and blister packed orthopaedic parts. In two separate inspection units the part-packaging is controlled by integrated vision systems. As part of a fully automated packaging line the inspection station can be adapted to a wide variety of samples. A high level of precise part feed and positioning is provided by a robot and a rotary table. Half- or fully automated operation is possible.

IMSTec’s fully automated packaging station includes the skin and blister pack inspection station used for 100% quality check after packaging of orthopaedic implants. A robot handling system moves a blister pack to the turntable of the inspection station-no. 1 for blister inspection (Tyvek Sheet). When inspection no. 1 process is finished the turntable moves the inspected blister pack into the unload position. A second robot picks the blister pack and places it to inspection-no. 2 for blister pack surface test (all 4 sides of blister pack).

After completion of inspection-no. 2 the robot transfers the tested part to the unload conveyor for rework or for loading it into the end of line buffer station. The system is designed to be used under cleanroom conditions. Inspection system no.2 consists of two cameras with LED illumination. One camera mounted on the lower part of the inspection station is used to inspect package top side. The second camera installed at the upper part of the inspection station is used to inspection the four sides of the part package. The inspection result is shown on the station HMI.

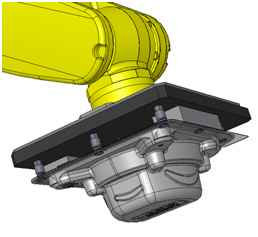

The skin- & blister pack inspect system requires no operator interaction. Parts are loaded and unloaded automatically by the robot system. The robot gripper is designed according part package geometry. Parts are held by vacuum.

A part presence sensor verifies that a part is loaded. Depending on process time requirement, several duplicated inspection stations can be installed. They work completely independent from each other which maximises the throughput.

In the standard version the inspection station does not contain any covers or safety sensors in order to allow complete robot access. Such devices can be added if the machine is supposed to be used in manual mode.