Process Solution

PART VERIFICATION SYSTEM

TECNICAL HIGHLIGHTS:

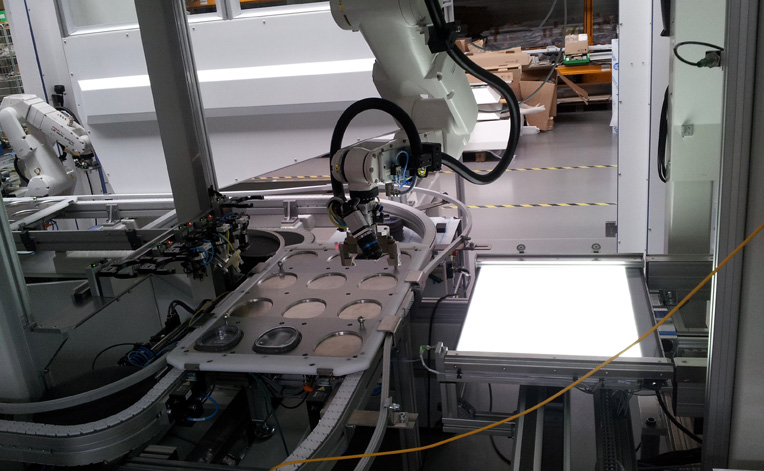

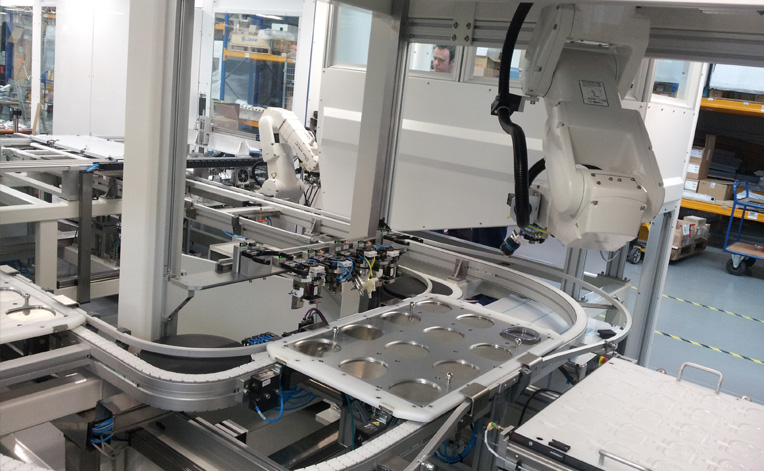

- Fully automated integration

- 100% in-line inspection

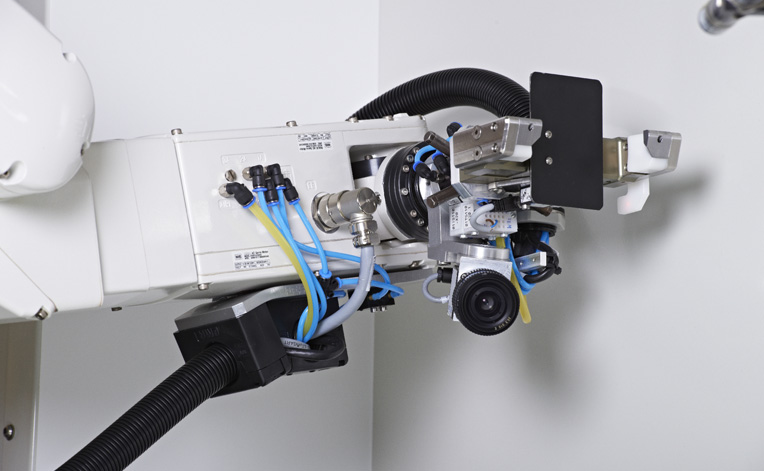

- Optical resolution 0.1mm

- Cycle time 16-24s

- Two CCD camera systems

- Laser scanner profile measurement

- Fast and precise robot handling

- Flexible gripping position adaption

- Feasible for medical products and cleanroom environment

- Adaptable for a wide product range

- Minimal user interaction

- Intuitive HMI design

The IMSTec Part Verification System provides fully automated verification of many different sample types in parallel such as orthopaedic implants. A robot gripper ensures highly flexible and precise handling of the products. The geometry of every part is measured and compared to the specification. An included gripper station provides adapted robot grippers for all products.

Technical data summary

|

|

|

|

|

|

|

|

|

|

|

|