Process Solution

INTEGRITY TEST STATION

TECHNICAL HIGHLIGHTS:

- Fully automated integration

- Leak detection down to 100µm

- Fast and precise robot handling

- Small footprint: approx. 230x235 mm² (depending on products)

- Feasible for medical products and cleanroom

- Several stations in parallel

- Modular design – number of stations adapted to user requirements

- 100% non-destructive inline inspection

- Adaptable for a wide product range

- No user interaction necessary

The IMSTec Integrity Test Station is a fully automatable station for integrity testing of skin and blister packed samples. The machine can be adapted to a wide variety of samples. Manual or fully automated operation is possible. Several stations can be operated in parallel depending on the required process time.

DESCRIPTION:

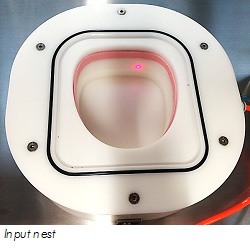

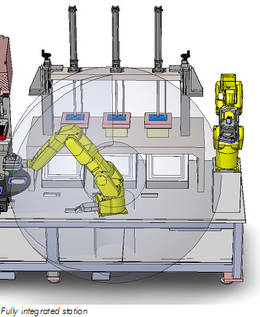

IMSTec’s fully automated packaging station includes the integrity test station for skin packs and blister packs used for packaging of orthopaedic implants. Function of the station is a 100% inline inspection without damaging the product. Up to three samples can be inspected in parallel independent from each other. The precise and fully automated robot handling ensures safe part transportation. Manual operation is possible by using the included touch screen controllers. The whole system is designed to be used under cleanroom conditions. Each integrity station consists of an input nest where the part to be inspected is placed and a top cover that can be moved up and down.

In the automated version the integrity testing process requires no operator interaction. Parts are loaded and unloaded automatically by robot system. A part presence sensor verifies that a part is loaded. Then the inspection process is started automatically. The top cover moves down to seal the input nest. Vacuum is pulled and hold for a defined time. Absolute and differential pressure measurement indicates whether the tested package is properly sealed or not. Leaks down to a size of 100µm can be detected. Due to the operating principle the leak detection is completely non-destructive. All produced samples can be inspected in-line.

According to the required process time several integrity test stations can be installed. They work completely independent from each other which maximises the throughput. In the standard version the integrity test station does not contain any covers or safety sensors in order to allow complete robot access. Such devices can be added if the machine is supposed to be used in manual mode.